As the material of choice for exterior and interior design, ALUCOBOND provides a seamless transition of color from indoor to outdoor spaces. ALUCOBOND products are chosen for outstanding attributes such as flatness, formability, durability, and ease of fabrication. Made in the USA, ALUCOBOND is manufactured in a range of sizes and trend-forward colors and finishes, both Standard and Non-Standard. Furthermore, our array of options lend to creating inspiring architectural concepts and bring brand designs to life.

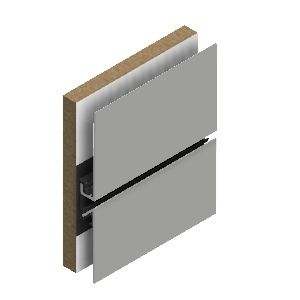

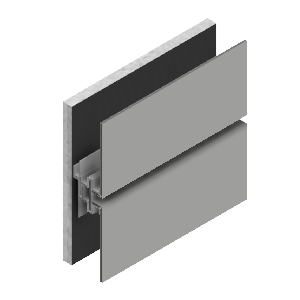

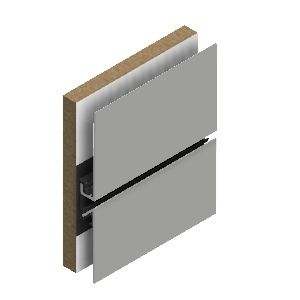

ALUCOBOND PLUS is a high-quality, lightweight aluminum composite panel renowned for its durability, design flexibility, and exceptional performance in exterior cladding applications. 91 colors and finishes give shape to great ideas.

ALUCOBOND offers a versatile and stylish solution for interior applications, featuring a lightweight aluminum composite panel that combines durability, design flexibility, and aesthetic appeal to enhance the ambiance of any space.

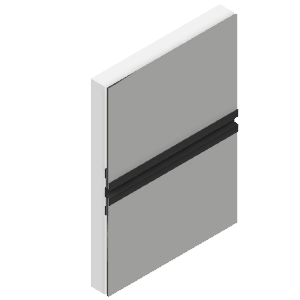

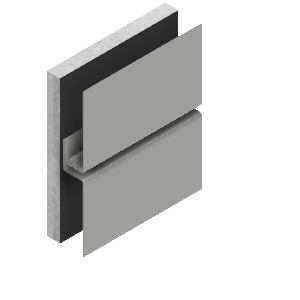

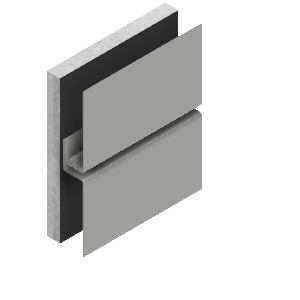

ALUCOBOND EasyFix is an efficient solution for both interior and exterior applications. This innovative attachment system offers easy fabrication, easy installation, and a wide range of design options, making it a versatile choice to elevate any space.

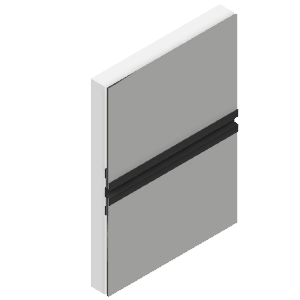

Whether for trim or interior and exterior cladding, ALUCOLUX is a flexible and reliable choice with multiple thickness options for specific application needs. ALUCOLUX caters to diverse project requirements and ensures optimal performance and aesthetics.

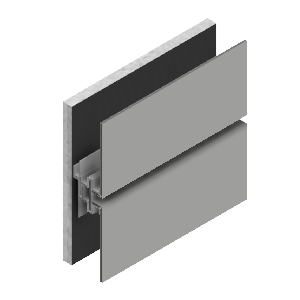

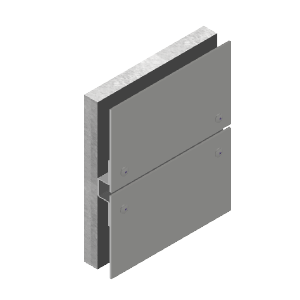

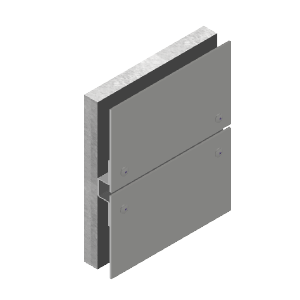

Designed for use in a wide range of applications, this simple screwed ACM system utilizes ALUCOBOND FaceFastened Attachment Rails and ALUCOBOND FaceFastened Attachment Screws to create a seamless, flush-mounted appearance.

“It was satisfying to see our design vision come to life on the GradLabs building,” said Justin Manor, Director of Innovation, at SOSO. “ALUCOBOND PLUS made it possible to execute our renderings at scale, with precision. Each panel is unique, with tight specifications to ensure the legibility of the overall form. The results are beautiful, functional and they align with the critical work being conducted by the teams inside”

Justin Manor

Director of Innovation, SOSO

Color plays an integral role in the architectural environment. From classic neutrals to biophilic hues and dynamic patterns, we offer a wide range of options to help give shape to great ideas.